Etching

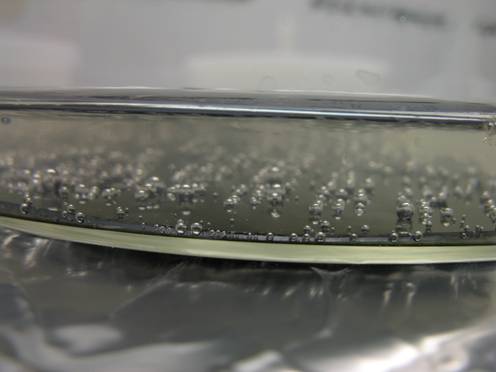

Using a strong acid called TetraMethyl

Ammonium Hydroxide we are able to etch away the silicon to form cantilever

beams with a thickness of 20 μm.� Below is a picture of a wafer in the acid.� Note the bubble protruding from the

surface.� This is the hydrogen being

released after the reaction.

Here is the most recent run of backside etching.� Although the etch time stayed constant with the

rate in prior runs ~30 μm/hr the etch was far from

uniform causing over etching some places in the wafer this can be seen below.

Feeling fairly confident that the doping has gone well

and resistors/contacts will perform if devices are released.� The final stages of the design will rely

heavily on understanding and controlling etching parameters.