With growing concern due to climate variation, it is important to create measurement systems to monitor the presence and concentration of elements, molecules and particulates in the atmosphere. This team proposes the design of a low-power solar spectrograph that will measure the relative intensity of H2O Fraunhofer lines (absorption lines) in the atmospheric solar spectrum. Through the design of a durable weather-resistant system, long-term measurements of Fraunhofer lines will be collected at accessible or remote locations to monitor the changes in atmospheric gas concentrations.

Water vapor Absorption lines (Frounhofer Lines):

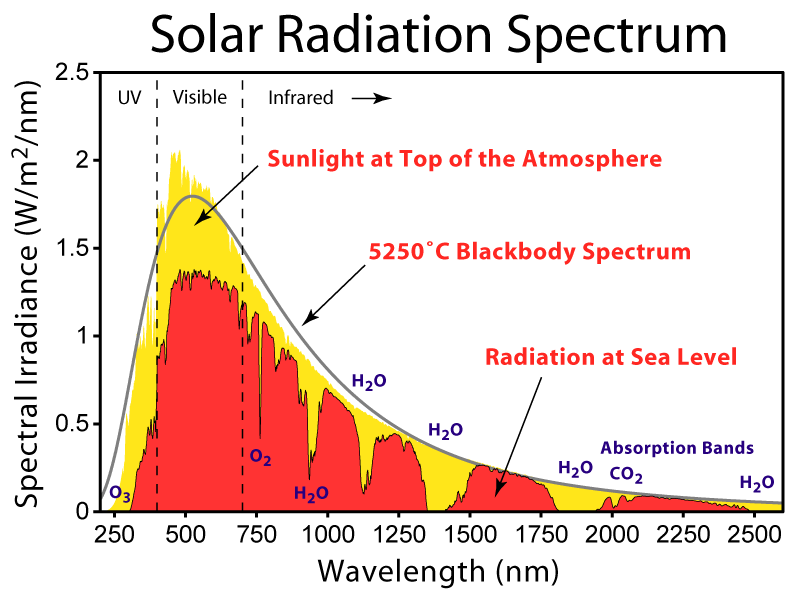

The sun which is often considered a black body radiator emits a broad

spectrum of radiation that travels through the earths atmosphere. The

plot below shows the total outer atmospheric sunlight (yellow) fits a

Blackbody spectrum curve. When the radiation has reached earths surface

certain wavelength ranges will have been absorbed by atmospheric gases

(red). Note that there is a large section missing around 800nm

labeled H20.

A Solar

spectrograph is an instrument that captures radiation from the sun and

separates this radiation into its individual wavelengths. With a known

spatial

separation of individual wavelengths spectrographs can be engineered to

accomplish a scientific goal. There are different variations of

spectrographs

however most share some specific characteristics to accomplish their

tasks,

these characteristics include capturing light from the sun, spatially

filtering

it through an aperture, collimation of the captured light, separating

the

wavelengths with a diffraction grating or prism, focusing of light onto

a

detector with a focusing lens or mirror. In this design a reflective

diffraction grating is used to separate the wavelengths and a focusing

lens is

used to focus the separated wavelengths onto a sensor. A CMOS sensor

was used

in this design instead of a photodetector which would require a motor

to scan

the individual wavelengths across the sensor.

The novel part of this spectrograph design is how the light is collected from the sun at various angles across and above the horizon. Generally, solar spectrographs light input slits or apertures are pointed directly at the sun. With this spectrograph design a light diffuser will be used to diffuse light incident at a maximum of 23o, such that enough of the scattered light is captured by the system. Holographic diffusers shape the diffusive light profile for higher sensitivity applications where higher transmission power is a necessity. A holographic diffuser set was obtained and tested for transmission and angular independence for this spectrograph system.

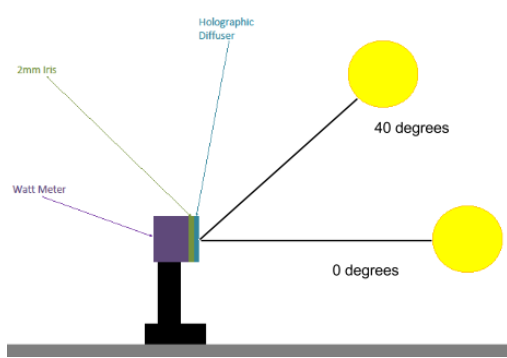

To test the holographic diffuser an open

faced optical power meter was used. A 2mm pinhole aperture was screwed

onto the

face of the detector such that the aperture remained approximately 1cm

from the

face of the detector. The holographic diffuser was then taped over the

pinhole

aperture where it remained approximately 5 mm away from the aperture.

A

protractor was taped to the center of the apparatus and by using a

ruler a 40

Watt light bulb was stationed 12 inches from the center of the

apparatus. A

two-dimensional diagram of the setup can be seen below. The light was

initially

held at 0o and moved up in 5o increments to 40o

while remaining 12 inches from the apparatus. This test was done with

two

different holographic diffusers, a 20o and 60o diffuser.

The rating of these diffusers is in regards to the maximum angle at

which they

will transmit optical power when light has normal incidence on its

surface. The

power relative to a control group incident on the detector was measured

and

plotted in Matlab. The control group was defined as the light bulb

normally

incident on the system with no diffuser blocking any light. These

values can be

seen over the range of input angles in the plot below.

The diffraction grating could be

considered the most important component of the spectrograph system.

This

importance is reinforced by the fact that it has been

mentioned so much in earlier sections. Without some type of grating or

prism

there would be no way for light to be separated into its individual

wavelengths. The three gratings that were considered for this design

were the

Richardson 53-*-260R, 060R, and 290R reflective diffraction gratings.

The

grating that was selected from the three options was the 260R grating

with 600

grooves/mm and 8.6o blaze angle. The efficiency for this

grating can

be seen below.

The minimum optical power required for

the CMOS sensor chosen for the system is specified to be 2nW/mm2.

In

the holographic diffuser test the diffuser efficiency at the most

extreme angle

seen in this system (23o) is approximately 20%.

This empirically

observed parameter is shown below in the Parameters

section below. Additionally, sun approximate

specifications, slit and camera area, and grating and camera

efficiencies were

taken into account at the center wavelength (800nm) for the purposes of

the

power budget calculations. The calculation flow and calculations below

show

that the theoretical intensity incident on the camera is 31.8nW/mm2.

This value is greater than the minimum camera specification, and it was

therefore shown that the system should function correctly with a

holographic

diffuser at the input. These calculations do not take into account

additional

power collected from a cylindrical lens, or power lost inside the

spectrograph

system.

Spectrograph Design:

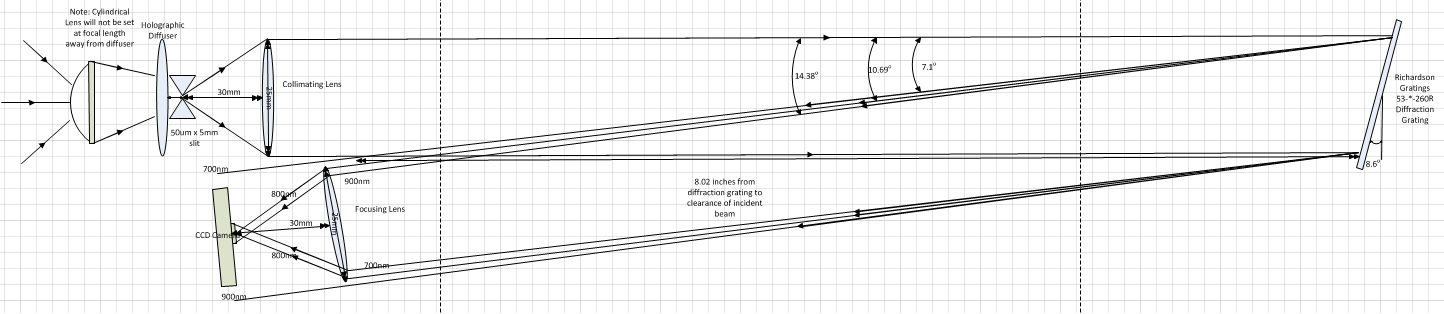

A collimating

lens will be placed the focal length, 30 mm away from the slit. The

focusing

lens will be place about 8 inches from the face of the grating with the

sensor

placed at the focus, 30 mm. The lens is placed 8 inches from the

diffraction

grating face because it will take around 8 inches for the diffracted

rays to

clear the incident collimated beam. This also sets the distance between

the

collimating lens and diffraction grating to be at least 8 inches. The

focusing

lens will be angled at 10.6o such that all of

the 800 nm rays are

captured at a normal to the focusing lens. This will result in the 800

nm

wavelength of light to be focused in the middle of the CMOS sensor. It

is

inherent that not all of the light reflected off of the grating will be

captured by the focusing lens as the spot size incident on the grating

is equal

in diameter to the focusing lens. The beam then proceeds to elongate in

the

dimension of spectral spreading this causes vignetting of the slit

imaged

spectrum when a fraction of the beam is captured by the focusing lens.

This

results in the extreme wavelengths at 700 nm and 900 nm to have a lower

relative power on the sensor face compared to the 800 nm wavelength

which

should be entirely captured on the sensor. When the system is being

prototyped

an effort to maximize power captured by the focusing lens will be made

by

adjusting the incident angle of the diffraction grating such that the

focusing

lens can be moved closer to the grating, decreasing the effects of

vignetting.

A diagram of the Lens optical design layout can be seen below.

The

system housing

will be assembled using a metal frame in order to ensure stability and

a planar

system. Aluminum sheets will be cut to the desired dimensions. Then,

the sheets

will be bent and welded together in order to create the housing box and

frame. The

box must be designed to be optically insulated. If any external light

enters

the system except through the optical slit, any optical power

measurements will

be compromised. To accomplish this optical insulation, the inside of

the box

will be painted with a low-reflection black paint in order to absorb as

much

undesirable light and reflected light as possible. The top and bottom

box

covers’ edges will be will be sealed with foam strips in order to

create a

system that is insulated optically and from moisture and weather. The

optical

components will be mounted on an aluminum mounting plate. The optics

will be

mounted on this aluminum plate using lens mounts, posts and post

holders from

Thor Labs. The slit and diffraction grating will be mounted on the edge

of the

box, as opposed to mounted internally as shown in the figure. This will

help

minimize any additional light entering the box. Currently, the slit

aperture is

specified to be 5.32mm tall and 50um wide. This size will accommodate

the

height and power specifications of the camera. The slit may be widened

to

increase power while sacrificing resolution, or narrowed for the

opposite

effect.

This budget does not include costs that

will factor into construction of the optical system housing. However,

there is

room in the budget to account for the creation of the housing system.

Specifically, 160 dollars remain for housing construction.

Additionally, some

aspects of the design may be cut from the system. The optical post

holders are

not necessarily required. Instead, the optics could be mounted by hand

to

decrease price. While the post holders would make mounting simpler,

they are

not required. The most expensive element in the design is the CMOS

Camera. It

is required, however, because it is able to operate under low input

power

conditions, which will occur in this system. The diffraction grating is

supplied by Richardson Gratings free of charge, and does not count

toward the

budgetary constraint. Additionally, a laptop computer may be used

during the

competition to obtain and interpret data. The aluminum mounting plate

and other

mechanical aspects of the design will be machined and altered in

Montana State

University’s machine shop.