|

Wireless Robot Engineering Constraints |

Tim O�Neil, Ivan Van Dessel, Conrad Donovan, 492 students

Abstract�Engineering

Constraints for the Wireless robot senior design project at

Keywords: Wireless Robot, ECE robot, CAN,

Controller Area Network

I.� Introduction

|

T |

HIS document

provides information on the most common non technical considerations for a

design project.� These factors are

analyzed to assess every possible impact the project could have, what it would

take to produce it, and how inflexible it would be to maintain the design.� This project operated under an ABET

accredited University for the entire duration of the design and

implementation.� The wireless robot

project at

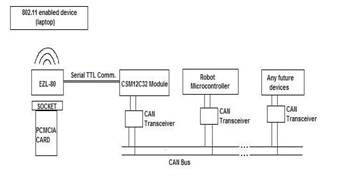

The interfaces between all of the components of the design are operated by the fabricated printed circuit board (PCB) that connects various components together:

� CSM-12C32 Module � This will handle the processing of wireless information and structure CAN messages to the and from the robot.

� Sollae EZL-80 � This will provide internal drivers to interface between a PCMCIA card and the CSM Module using TTL-level serial communication.

� PCMCIA card and socket � This is used to receive wireless signals and provide a connection between the EZL-80 and the PCMCIA card.

� CAN Transceivers � These are used in combination with the MSCAN 2.0 system built into the HCS12 processor contained in both the CSM Module and the robot microcontroller.

The primary function of the wireless interface on the robots is to send and receive data from a robot to a central server. The data can be a combination of commands, path direction, time, and speed. Secondary goals are robot-to-robot communication and laptop-robot code debugging and loading. For additional information please go to the project website at http://www.coe.montana.edu/ee/seniordesign/robot_wifi/ .

A.� Economic

The economic effects of this project are as follows.� First there is the robot kit that runs $109.50 from the MSU ECE stock room.� This is the only cost for the actual robot because the soldering and construction are done as part of the EE 101 course.� The second cost is the cost of the wireless daughterboard.� Including shipping and handling from PCB express the boards came to $43.50.� It should be noted that the price of these boards is directly proportional to the number ordered at one time.� For example it cost only ten dollars more to order four boards as apposed to two.� If the ECE department decides to order several for one of their labs it could come out to a much smaller cost for each board.� The parts that populate the board on the other hand are a more constant price and it should be forecast that it will cost relatively close to the $66 we paid to populate one of the boards.� This amount could be slightly changed due to bulk orders on parts but that is entirely dependent on the part and the company providing it.� Another important piece that is required for this system is the Motorola CSM 12C32.� This important piece of the system cost $59 each.� The EZL 80 produced by Sollae, another important component of this system, cost $56. Then there�s the wireless networking card comes in a wide range of prices.� The average cost is about $30 though there are some that start around $12 and others that are closer to $100.� Our design team is currently experimenting with a variety of different cards and has yet to settle on a specific brand.� Another cost to keep in mind for production is the cost of soldering the daughter board.� It is this team�s understanding that the ECE department will be buying a number of these boards as lab equipment. If that is the case someone will need to solder those boards together.� The actual time it would take to do this is yet unknown but it is estimated that a person experienced with soldering could complete a board in around three hours.� This cost would be a factor in the end result price and should be kept in mind.� Another cost to factor in is the cost of batteries to run this product.� This cost could be left up to the student, but it may also be include with the initial price. Lastly talking to the robot will not be a cost because any campus computer loaded with the software developed by this team and a connection to the campus network will be able to communicate with one of the robots.

B.� Environmental

The environmental constraints on this project are relatively few.� One item is the lead based solder. Due to the fact that lead is poisonous to humans when ingested this product should not be eaten and should be kept out of reach of children. Another item to be considered is the power source.� The power source is controlled by a LM7805 power regulator that releases excess power through heat and it is possible to burn oneself on this device so caution should be observed.� Another constraint network safety should not be a major problem due wireless encryption protocol.� It is possible for a person to hack in if they knew enough specifics of the project but it seems unlikely.� Also it is possible for other wireless devices to interfere with the robot but no more so than normal.� Installation, Maintenance guidelines, Telephony voltages, Electromagnetic emissions, and humidity were considered and deemed not to be a problem because of the specific destination of this product

C.� Manufacturability

The manufacturing of wireless project consisted of the design of the wi-fi add-on board which was mainly designed by Chris Stephani, and co-designed by Tim O�Neil and Ivan Van Dessel. The design for the wireless robots requires the production of a printed circuit board (PCB). The PCB will connect the EZL-80, CSM Module, and PCMCIA card and socket.� It will also provide pin outs for the CAN bus to be connected to the robot microcontroller.� The PCB design will be on file, so it will be easy to reproduce when more are required.� The fabrication is simple, containing basic connections and relatively large components. The most complicated component is a four-row PCMCIA socket with 68 pins that is difficult to solder but manageable and necessary. The other more advanced soldering parts would be the smaller capacitors and resistors that are located on the board, but will also not be a problem for beginner solders. CAN is a simple two-wire bus structure, limiting connections on both the robot and CSM Module.� The CSM module and EZL-80 need only four connections for serial TTL communication. (Figure 1) These decisions simplified the PCB design and the connectivity between the PCB and the robot.� The manufacturing of the add-on wi-fi board was designed to the specifications in which it could be attached to another device that accepts CAN-BUS architecture.�

Figure 1

Overall architecture of the wi-fi board attached to the ECEbot

D. Sustainability

Sustainability

has been a major design consideration for the wireless robot.� There is a goal to make it available for

long-term use in ECE courses at

E.� Health and Safety

The main health and safety issue to not interfere with other wireless networks and communication because this could cause many communication problems that could be serious.� As a result we will rely on the IEEE and its compliant standard the 802.11b.� This standard has international recognition and is a safe bet for future use.� The task group that created the standard was formed in 2000 and consisted of more than 100 networking and software companies as well as those from consulting agencies and academic institutions.� The data rate of the Wireless LAN Medium Access Control (MAC) was improved in 2003 from 11 Mbps to 54 Mbps by using (OFDM) orthogonal frequency division multiplexing.� This new standard 802.11g is backward compatible with 802.11b.� The data rate 11 Mbps is enough to support many robots and other devices using this standard as well as others using the new 802.11g standard.�

F.� Social

The social issues include the following:� education and regional studies, community research in rural and urban environments, communication, popular culture and social change.� Education and regional studies could be improved by using the robot to collect various data from dangerous or hard to reach terrains.� The data would then be used as educational or scientific material.� Community Research in urban and rural environments can be improved by using the robot to collect data over the terrain.� In the future data such as audio, video, temperature, humidity and still pictures could be collected as the robot moved across the terrain.� Also the robot could be used exploration of other planets, etc.� Communication between people and organizations will improve because the robot in the future could be used to relay messages or do a video broadcast.� Popular culture could change by adding enough features to the robot.� The robot could be marketable for the consumers.� Maybe in the future people would own the robot to set a social trend.� Society will be changed as a whole because people will rely more closely on robots to collect data.�

G.� Political

The political issues including

the following:� civil and political

rights, diplomacy, international migration and colonization and international

relations.� Civil and political rights

are not violated in this project because there is not a law in the

II.� Acknowledgment

The authors gratefully acknowledge the contributions of Dr. R. Wolff project advisor, Carson Drew, Brad Benjamin, and Chris Stephani for their work on this project.

III.� References

Technical Reports:

[1] Sollae

[2] Axiom Manufacturing. CSM 12C32 Educational Module for Freescale MCS9S12C32 [Online].� Available: http://www.axman.com

[3] B. Benjamin, �CAN (Controller Area Network) Documentation for groups using CAN with the ECE robot with the Motorola HCS12 processor,�� 2005

Standards:

[4] IEEE Wireless standards development, ANSI/IEEE Standard 802.11, 1999 Edition (R2003).

VI.

BIOGRAPHIES

Tim O�Neil was born

�Ivan Van Dessel, was born

�Conrad Donovan

was born in