Key Accomplishments

Developing A General Design

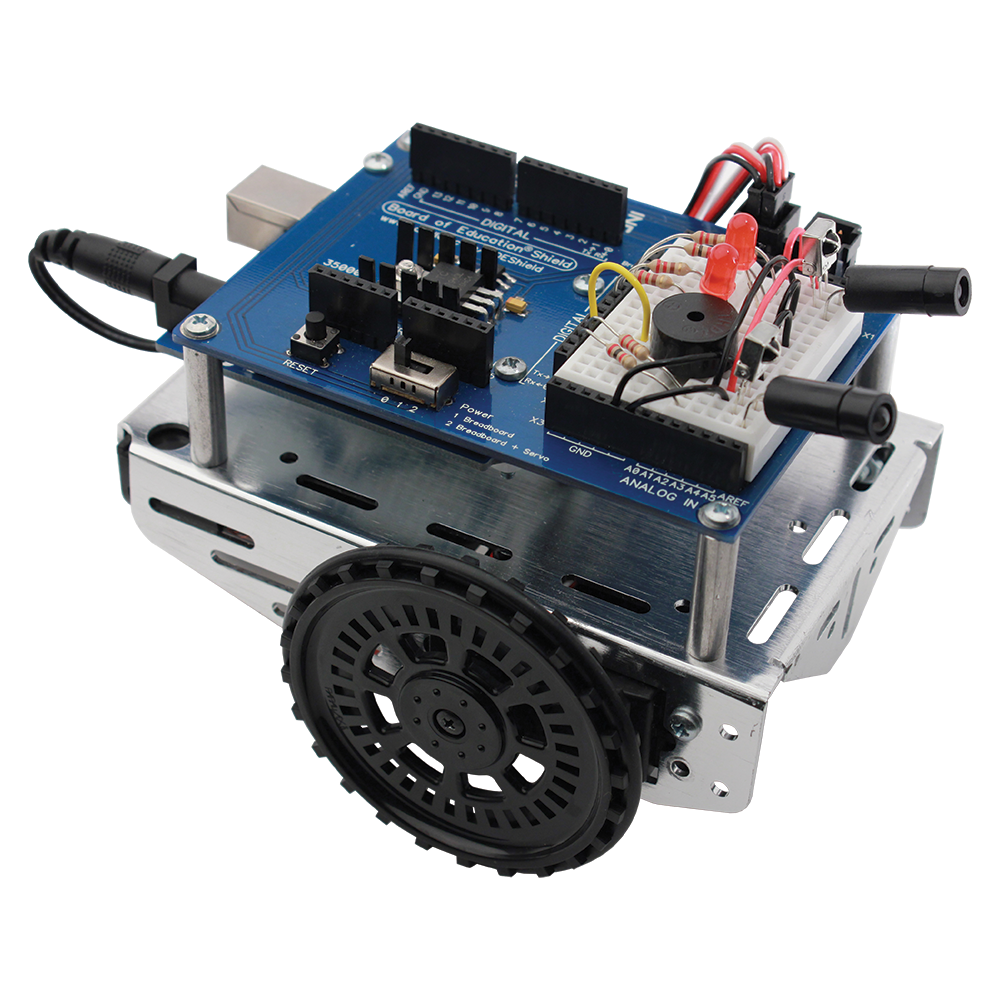

BOE Shield Bot

Often the hardest part of any project is getting started. Seemingly limitless options can invoke a sense of directionlessness. Fortunately, we were given the EELE 101 Parallax Boe Shield Bot as a baseline for our project. Any modification could be made. It was soon discovered that the included QTI sensors were both reliable and effective. Through this, a general design could be built around these very sensors. This included the microprocessor fast enough to analyze and manipulate the data received from the sensors, a servo motor that could interface well with that processor, DC motors that could be run from the microprocessor, a battery to power it all, and the chassis to hold it all. This gave a rough outline of our desired components which could be found below.

- QTI Sensor

- Arduino Uno Microprocessor

- 1 High Torque Servo Motor

- 2 High RPM DC motors

- High Capacity Lightweight Battery

- 4 Thick Wheels for Traction

- 3D Printed Plastic Chassis

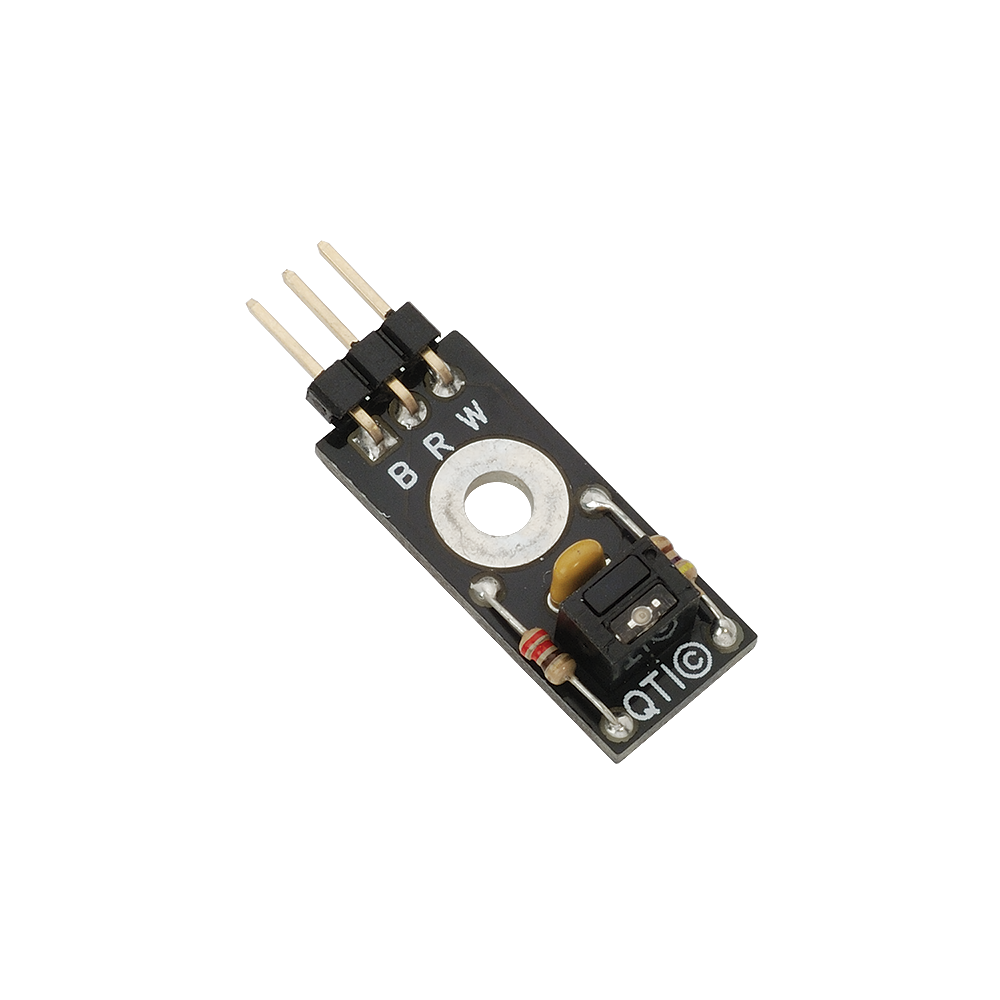

Interfacing QTI Sensors

QTI Sensor

Current QTI testing results have confirmed the effectiveness of these sensors. This integral part of our system was placed on an old EELE 101 car (Freescale Cup Intelligent Racing Car) and controlled the Futaba s3001 servo motor. Being able to integrate these sensors to a servo motor and have them accurately record data and move the servo is critical to our design. The foundation of the project is built on these sensors, and seeing them work accurately is an enormous milestone. The sensors will eventually be implemented on a different servo motor with a higher torque and rotation speed. This will drastically improve the performance of our steering and tracking system.