MEMS

Fabrication�

Micro-Electronic Mechanical Systems

By

Andy Lingley, Matt Leone, Brad Pierson

&

Faculty Advisor Todd Kaiser

Project Goals:

�

To obtain

multiple working MEMS devices on a single wafer, and to quantify their results

�

Build a lab

manual capable of walking undergraduates through the process in a fifteen week

laboratory

Scope:

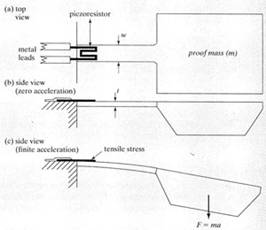

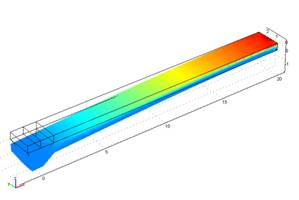

����� Accelerometers and pressure

sensors were chosen as the MEMS devices.�

It was imperative to understand the devices before the process steps

were developed.� The picture seen here gives

a great illustration of the accelerometer design.� A simple cantilever beam will flex as a force

or acceleration is applied to the proof mass.�

Using the piezoresistive affects of silicon a change of voltage can be

measured as the silicon is deformed.� The

piezoresistive affect is a change of resistance due to a change in crystalline

shape on the microscopic level.

����� Accelerometers and pressure

sensors were chosen as the MEMS devices.�

It was imperative to understand the devices before the process steps

were developed.� The picture seen here gives

a great illustration of the accelerometer design.� A simple cantilever beam will flex as a force

or acceleration is applied to the proof mass.�

Using the piezoresistive affects of silicon a change of voltage can be

measured as the silicon is deformed.� The

piezoresistive affect is a change of resistance due to a change in crystalline

shape on the microscopic level.

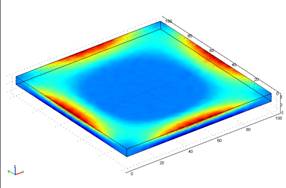

Many devices can be made

utilizing these peizoresistors.� In our

case we also designed a few pressure sensors and a tactile sensor.� By simply fixing four sides of a square and deforming

the middle, a strain will be created at all fixed points.� This is similar to the fixed end of the

cantilever.� Below are two simulations of

actual designed devices. This simulation was run prior to completion of the

mask design.�

��

��

The Process:

��������� The fabrication process can be broken up into five

simple steps.� Below is a flow chart of

these steps followed by a short description of what each step should

accomplish.� Clicking on the flow chart will

take you to a link with the all steps required to build an accelerometer.

Note:� Each Step has a link discussing step

specifics to our Accelerator and Pressure Sensor Design.

��������� Mask design is crucial to success in

all microfabrication.� All masks must be

able to be aligned and all measurements must be precise, taking into account

etch planes and doping times.

��������� By

growing a small layer of glass on a silicon wafer, it can serve as an insulator

for future steps in the process. This glass can be grown on silicon by simply

exposing it to oxygen under high temperature (1000 C) growing SiO2.�

~Photo Lithography:

��������� A thin

layer of photoresist will be applied on to the SiO2, then

this photo resist will be patterned with a mask and exposed to UV light.� This UV light breaks down the exposed resist

leaving the desired pattern after development.

��������� With a pattern of exposed silicon

on the wafer, etching cuts the desired shapes into the wafer.� The crystalline planes of silicon will cause

this etching to be done at some angle.�

In our case, a chemical called Tetramethyl Ammonium Hydroxide (TMAH)

will be used, resulting in an etch angle of 57.4 degrees.

��������� This

step is done instead of etching if different electric properties are

required.� By choosing the proper chemical,

electrons and/or holes can be made in order to fit specifications.� This is often done in order to create

resistors on a wafer.

�And now let�s meet the Team:

�������������������������������������������������������������

����������������

Matt Leone Andy Lingley Brad Pierson

��

���������������������������������������������������������������������������

���������������������������������������������������������������������������

Faculty Advisor Todd Kaiser

MMF Home

Page / Member Biographies

Page made in support of EE 492 and also the continuing

research in the Montana Micro-Fabrication Facility, optimizing discussed

topics, and furthering understanding of all process steps.